The elastic nature of your workforce makes it necessary to have accurate and timely labor cost visibility.

You’ve been forecasting your labor needs according to your anticipated volume and customer requirements. But now you are blowing past budget and aren’t sure why. This article helps you get to the root cause. What causes your teams to exceed their labor budget, and was your allocation correct to begin with?

Let’s start with knowing exactly what influences your labor cost. Accurate allocation of labor spend across product types, customers, and processes, enable your team to plan for labor with confidence, and avoid surprises.

The purpose of labor management systems, warehouse management systems, and other such tools is to reduce costs and improve productivity over time. But if you’re struggling with labor cost budget overruns, it’s probably time to go beyond productivity metrics and gain full transparency into your labor costs, and what influences your labor costs. In order to get your labor spend on track, you need to identify the underlying causes of the problem before you can fix them. You can start by asking these questions:

- Is your product volume higher than you predicted and budgeted for?

- Did you under-budget your overtime and wages?

- Did you use more overtime than you planned for?

- Could increased waste have been the cause?

- Are you running an excess of Missing Time?

- Is your productivity running below standard?

- Are you efficiently utilizing your onsite equipment?

- Have you communicated labor spend targets to your managers?

- Does your labor budget reflect changing business priorities, or is it “set it and forget it”?

Any and all of these questions could lead you to the source of your surprise budget overruns. They will expose whether or not the team is operating efficiently and whether or not your labor costs are realistically matching your volume and workflow. But you’ll need data to answer them.

Drilling Down For Answers

Each of these questions may look straightforward on the surface, but more specific answers can be found by digging deeper into the data.

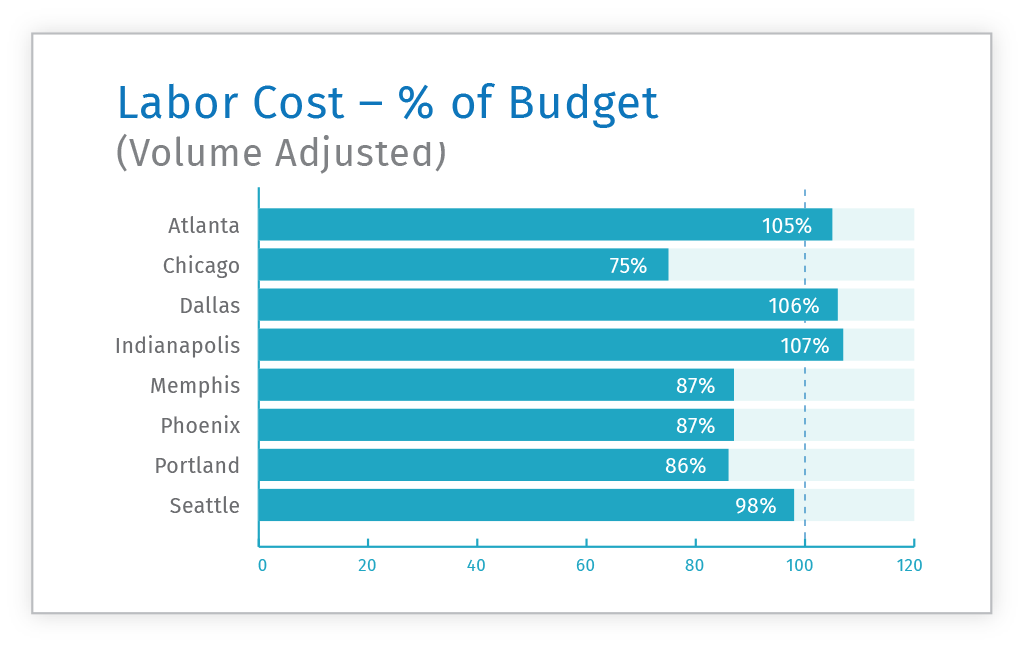

Let us put forward an example case: Company A has noticed that it’s running over budget, and takes a look at the data available. They’ve spent $2.5 million more than their allocated budget—a 23% overage. That looks bad, so they decide to investigate. The data reveals a 20% increase in volume across their facilities—which suggests that their costs are only 3% over what they should be with respect to the increased volume. So where does that remaining 3% come from? There are many possible answers, and the best way to find them is to again refer to the original list of questions and break it down by facility.

What is your overtime % across your facilities? What is your ELS% (productivity %), and how much could that be costing you? How much missing time do you have? These questions can guide you toward cost savings, while also helping you identify whether or not your budgeting issues are because of inefficiency, poor management, or merely changes in volume and customer requirements.

Automating Labor Budgeting & Forecasting

Our Operations Financial Management (OpsFM) solution is specifically designed to give you cost and performance visibility into your various processes and facilities, with the goal of driving out waste and running your operations network with full financial visibility. Easy Metrics’ OpsFM solution integrates your operations data, such as existing LMS, WMS, and timeclock systems to expose cost to serve so you can gain visibility into everything that influences your labor costs. With this information in hand, you can dig down into the data to answer each and every one of those questions, identify the source of the cost overrun problem, and begin planning the best course of action.

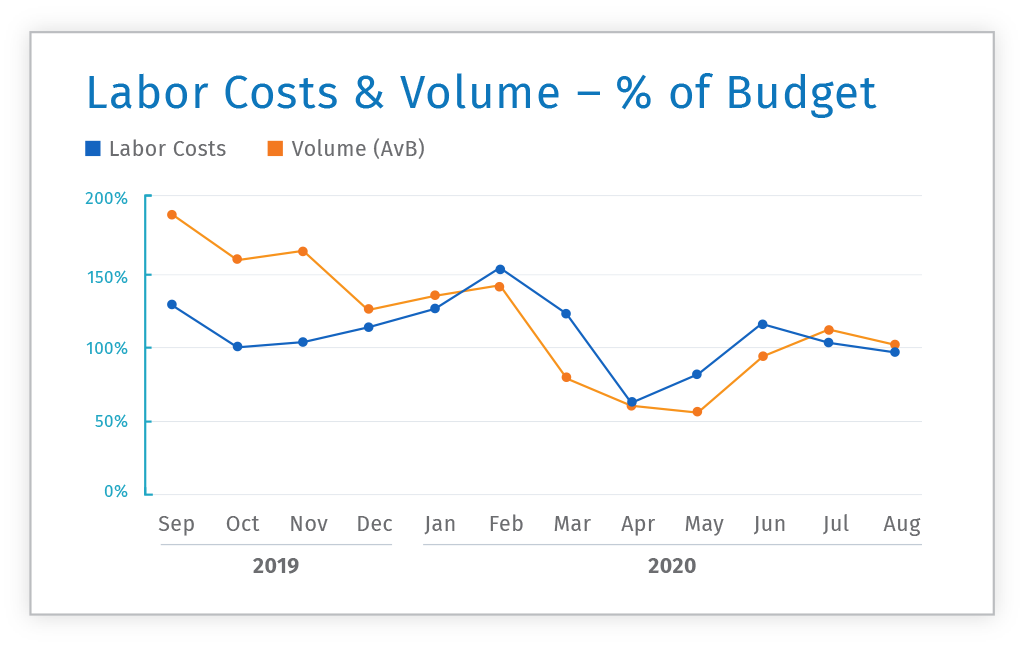

Our budget dashboard allows you to look at your budget, ELS%, Volume-Adjusted budget, Overtime %, and other critical metrics from a company-wide perspective. If you want to dig deeper, you can view the variances in budget by facility, and select any locations you’d like to examine individually. Long-term tracking and measurement of trends and relationships (like the relationships between budget and incoming volume) are also readily available. Easy Metrics gives you the tools you need to locate the discrepancy, identify the problem, and determine a solution so you can have a better and more accurate labor budget that your team can align with.

What About 3PL Profit Centers?

If you are a company that treats your distribution centers as profit centers, like a 3PL that charges the customer for the work performed, a purpose built tool for labor budgeting and forecasting is even more useful. Easy Metrics has a Profit dashboard that integrates with the Budget dashboard to give you an even more comprehensive overview of your operation. These tools are able to grant you unparalleled cost visibility into your operations, giving you everything you need to budget accurately and drive financial accountability across your team.

Setting and keeping within established labor budgets can be difficult, especially in today’s upended and dynamic supply chain environment. Both of those things require a solid, data-driven foundation to be effective, and we want to help you acquire that foundation. Easy Metrics’ Budget dashboard helps you eliminate errors and reduce your reliance on spreadsheets, stop getting surprised by budget overruns, and drive stakeholder buy-in and financial accountability.

If you’re interested in gaining visibility into what influences your facilities’ labor costs and align your labor spend to business priorities, contact us. We’ll show you how easy it is to get started.

Ready to have cost to serve analytics in your operations? Sign up for a demo of Easy Metrics today.