Objective and measurable employee performance standards are an excellent way to drive workforce engagement, improve productivity, and measure process improvement. The most common method of deriving performance standards is through the use of Engineered Labor Standards (ELS). This involves an industrial engineer conducting time and motion studies, data analysis, and industry best practice methodology to create a labor standard for every process an employee performs in an organization. We have seen tremendous performance improvements in organizations that proactively manage to labor standards. It has one of the highest ROI’s for a business process software.

However, labor standards are not enough. Adding in cost to serve with labor standards brings an entire new dimension of understanding to your work flow processes. Here is a case study we conducted on equipment type usage for picking and the resulting benefits.

Case Study

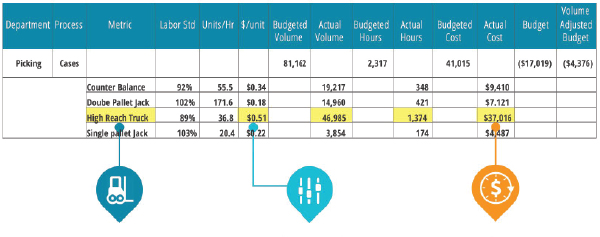

The company is a large 3PL that manages the distribution for a large US manufacturer. In their picking process analysis, they used 4 pieces of equipment for picking: Counter Balance Lift Trucks, Double Pallet Jacks, Single Pallet Jacks, and High Reach Trucks. Each piece of equipment has a different labor standard because each truck has different performance characteristics. The results are below:

As you can see, process performance is pretty consistent between each piece of equipment, ranging from a low of 89% on the high reach truck up to 103% on the single pallet jack. There are probably some improvements that could be made with high reach performance, but there’s no cause for alarm.

However, when you look at the cost to serve by equipment type, you see almost a 300% difference in cost between the high reach truck and the double pallet jack, not just the 13% variance you see in the performance standard. If you used only the double pallet jack for picking instead of the high reach truck, the labor cost variance would be $15,500 for the month. That is $186,000 a year in labor savings!

Using this new information, the company reconfigured their picking process to mainly use the pallet jacks and not the lift trucks. In addition to the labor savings, they were also able to eliminate the need for two High Reach Trucks, saving them about $70,000 in equipment costs.

Cost is always the ultimate measurement of process performance and improvement. While Labor Standards are invaluable tools in managing your work force, cost to serve is the most valuable tool in measuring process improvement.